8 Casing Spacers

SAE Housing Adapters & Spacers. Phoenix Casting & Machining manufactures a wide variety of SAE adapters to help with your special needs. Stock adapters are manufactured from aluminum or steel. Most components can be manufactured from special alloys to your specifications. Bore Spacer Examples for 8' - 16' Casing Sizes. 18'-24' OD Casing Bore Spacer Examples. Bore Spacer Examples for 18' - 24' Casing Sizes.

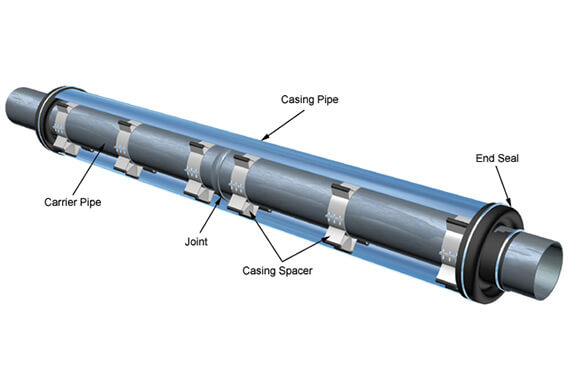

PSI provides for each combination of protective and carrier pipe the best spacer with matching casing end seal. Screwless spacers are available as well as the classic screw version for various loads. Casing Spacers & Casing End Seals. PSI provides for each combination of protective and carrier pipe the best spacer with matching casing end seal. Screwless spacers are available as well as the classic screw version for various loads. Casing-Spacers System DSI. Pipe Support Saddles. Casing Spacers / Chocks Custom Tee Box Markers The end products are primarily used by fluid and gas distribution construction industries for the repair, maintenance, and new construction of potable water and sanitary sewer lines, agricultural irrigation lines, natural gas distribution lines, and low-pressure oil.

CASING SPACERS & END SEALS

APS Casing Spacers center water and sewer pipes in casings with ease of installation, are virtually corrosion proof and provide insulating protection from a possible electrical shorting between the carrier pipe and casing. No special tools are needed, no grease is used and they are easily bolted on by a single worker. APS Casing Spacers eliminate the need to fill the casing annulus with sand which is extremely labor intensive. Sand in the annulus also acts as an electrolyte thereby introducing unwanted current to the steel or ductile iron. With no need for this fill, APS Casing Spacers are your answer to lower installation costs with continued access for maintenance.

Casing insulators are used to support and electrically insulate a pipeline from a casing pipe through which it must pass and are used in river crossings, canal crossings and bridge crossings as well as highway and railroad crossings. We recommend installation of polyethylene casing insulators every 6 to 8 feet.

* NEW FIELD-ADJUSTABLE RUNNERS FOR CASING SPACERS.

APS has recently developed Field-Adjustable Runners for Casing Spacers with 8' wide bands.

FACTS & ADVANTAGES:

STAINLESS (Model SSI) and CARBON STEEL (Model SI) SPACERS

Heavy duty two piece stainless steel or carbon steel bands by APS serve virtually every piping application and should be utilized inside casing that is 2 or 3 pipe sizes larger than the carrier pipe. APS steel band casing is available in two widths. 8' width is recommended for carrier pipe 4' to 24'. 12' width for carrier pipes 26' to 120' and larger. The band is constructed of 14 gauge steel with a 90 mil EPDM liner. Stainless steel spacers are available in grade 304L. Carbon steel spacers are available with a thermoplastic powder coating for extra corrosion protection.

INJECTION-MOLDED POLYETHYLENE SPACERS

Advance casing insulators are manufactured from injection molded high density virgin polyethylene. Benefits of polyethylene include high impact strength as well as abrasion resistance. Once installed, the low friction of polyethylene facilitates easy installation into the casing. Molded into the inner surface are grooves which prevent slippage of any carrier pipe coating. The Advance casing insulators have excellent dielectric resistance and low moisture absorption which yields minimal electric current loss and no impairment of cathodic protection. Sizes are available from 1' through 48' with a standard runner height of 1'. Casing insulators from 1' through 12' comprise two halves; two pi and four pi sections make up 14' and above. Advance casing insulators are lightweight, economical and easy to install. Only a screwdriver is required for installation.

CUSTOM FABRICATION

APS is capable of manufacturing spacers and end seals for specific customer requirements. Our engineering staff has experience in the following:

- Placing multiple carriers within one casing

- Positioning thermally insulated pipe without damage to insulation

- Centering small carriers within large casings

- Positioning gravity sewer to on-grade requirements

- Casing spacers for all types and sizes of pipe above 2'

APS CASING SPACERS: THE RIGHT CHOICE

Advantages: With proven dependability and ease of installation, Advance Products and Systems' casing spacers easily outperform the labor intensive, inefficient and unreliable wood skids. Just check the comparison below.

- Easily and efficient to install requiring no grease and no special tools

- Installation by one person

- Slides into place with ease. Coefficient of friction = .1

- Requires no backfill

- Decades of proven reliability

- Insulating and long term corrosion protection

SKIDS & STRAPS

8 Casing Spacers Plastic

- Difficult to install, cumbersome, time consuming and hard to secure accurately

- Requires several workers an extended time to position

- Very resistant to sliding often damaging skids enough to need replacement before installation is complete

- Requires annulus space filler, such as sand, pea gravel or grout

- High failure rate

- Non-insulating and allows bacteria and differential Oxygen concentration corrosion

END SEALS

Advance Products & Systems End Seals outperform the costly and labor intensive brick and mortar method of sealing casing ends. While soil stress and pipe movement cause mortar to crack, the APS products move with the pipe, insuring the integrity of the seal. And, unlike link-type sealing blocks that are limited to carrier/casing differential and can only be used on a concentric profile, the APS seals are totally flexible. APS offers four types of end seals which can accommodate any combination of pipe sizes.

The model AC and AM are seamless and can easily be pulled on at the time of construction while the model AW wrap-around is designed to facilitate installation when the carrier line has already been welded together and the pull is complete. Simply wrap around the carrier and casing, remove the release liner from the two pressure sensitive butyl mastic strips and press the adhesive strips down to form a seal. Model AZ, zipper type end seal, wraps around the casing end and carrier pipe and zips shut to provide a tight seal while still allowing for pipe movement. All four are made of 1/8' thick synthetic rubber assuring excellent chemical resistance and resiliency and are secured with T-304 stainless steel banding straps with a 100% non-magnetic worm gear mechanism to insure the integrity of the clamp. Only a screwdriver is required for installation.

In addition, Innerlynx forms a mechanical seal between pipelines and casing. Innerlynx forms a hydrostatic seal and electrically insulate the carrier pipe from the casing. Innerlynx can be installed by one person and requires no special tools.

8 Casing Spacers

| QUOTE REQUEST FORM

| |

DOWNLOAD STAINLESS STEEL CASING SPACER SPECS DOWNLOAD FUSION COATED STEEL CASING SPACER SPECS DOWNLOAD STAINLESS STEEL CASING SPACER ENGINEERING SPECS DOWNLOAD FUSION COATED STEEL CASING SPACER ENGINEERING SPECS | |

Model M-6, M-8 and M-12 casing insulators are made of 14 gauge, hot rolled, pickled, and oiled carbon steel galvanized . They feature an extra heavy duty vinyl liner, assuring double insulation.

| Band Gauge | 14 |

| Band Width | 6 ,8 and 12 inch |

| Band | Carbon Steel |

| Bolts, Nuts & Washers | Cadmium plated, or stainless steel |

| Insulating Liner | PVC or EPDM |

| Runners | 1.25 |

| Runner Tensile Strength | 17,400 psi (LDPE) 22,00 psi (HDPE) |

| Runner Flexural Strength | 25,00 psi (LDPE) 32,000 psi (HDPE) |

| Runner Comprehensive Strength | 17,800 psi (LDPE) 25,000 psi (HDPE) |

| Risers | 10 gauge steel on risers when used |